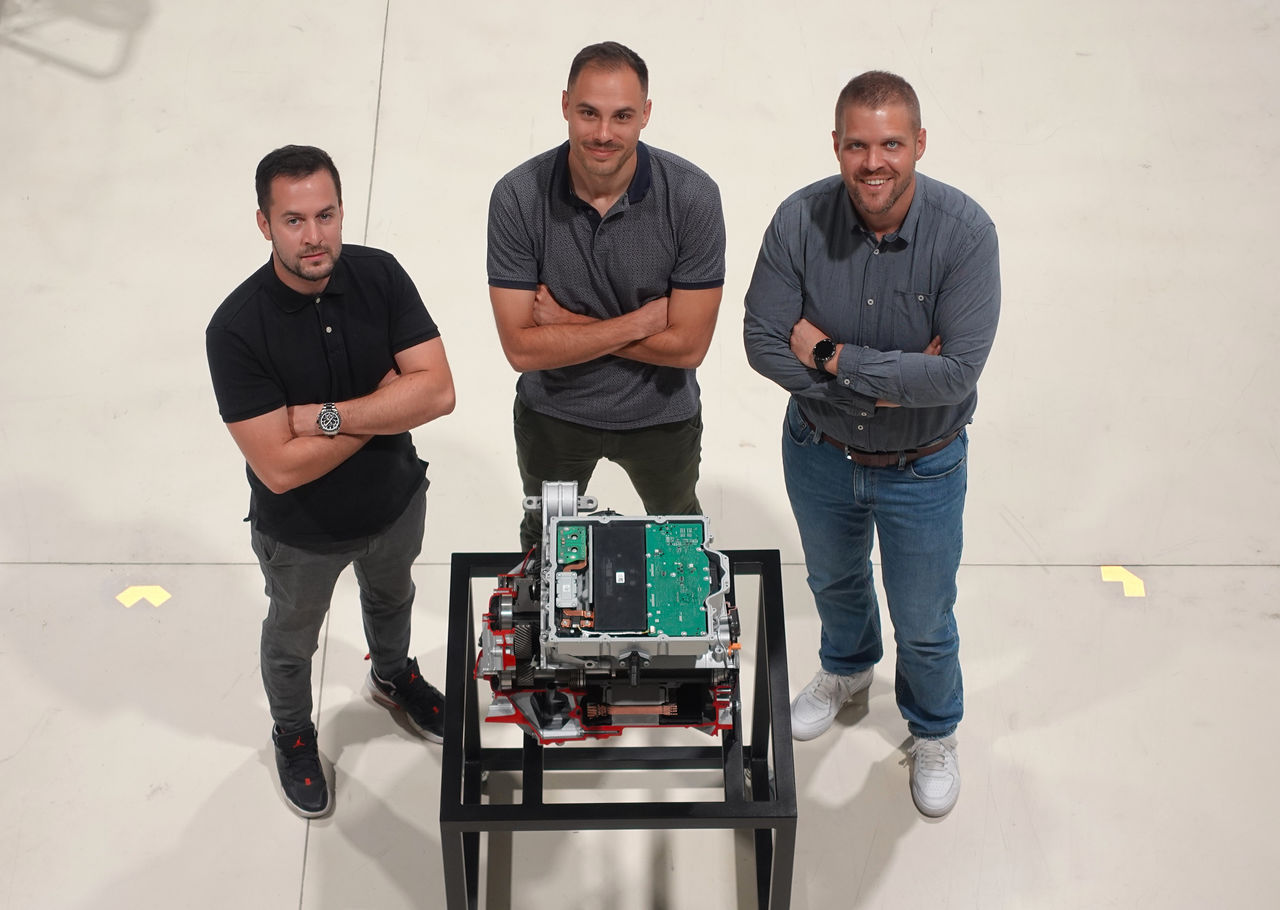

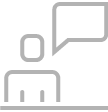

At Audi Hungaria, PPE electric powertrains are being developed for the Audi Q6 e-tron and A6 e-tron model series, as well as for the Porsche Macan and Cayenne models, which are launched on the world markets after a lengthy and extremely careful testing. While in the EU, North America and, among others, the South Korean markets, our experts perform measurements in-house on the company's accredited brake tester benches, the Chinese market sets the strongest and most complex requirements for both Chinese-made and imported cars. In practice, so-called homologation means that the results of measurements carried out locally at the independent test centre of the Chinese authority are accepted and officially accredited. Recently, as a result of the modification and tightening of the standard, three of our colleagues, László Kónya, Dávid Hertner and Tamás Rasovszky travelled to Shanghai to perform the tests. They spent a week and a half verifying the authenticity of the PPE power source data on behalf of Porsche, so that the powertrains built into the Porsche Macan and Cayenne cars could be launched on the Chinese market.

Certainly, some people find it disconcerting if a borrowed stationary item is not returned to its usual place, nevertheless, our colleagues proved themselves in a completely different working and linguistic environment, culture, among unfamiliar equipment, and in high-pressure situations, , which required considerable preparation on their part.

"The preparation of the tests, i.e. the homologation process itself, started long before the test by the administrative departments, as the coordination with the test centre had been going on for almost a year. We strived to make use of our period of stay as efficiently as possible, so we prepared, reconciliated and scheduled every aspect down to the smallest detail," says Laci, who has been working in the field of engine development at the company for 9 years after completing his internship with the SZEnergy team at the University of Győr. On previous similar assignments, he supported his colleagues from back home, so this was the first time he himself travelled to China.

"The test environment itself was familiar to us," Tamás continues, "because we worked with the infrastructure and standard procedures we were used to, so the process was not a challenge from a professional or linguistic point of view." After the start of series production, Tamás Rasovszky, who has since moved into project coordination, has a comprehensive overview of the e-drive models produced at the company. This was his third trip to China, so he was able to help his colleagues with his experience. Tamás emphasized the fine-tuning and thorough preparation in Hungary, so that the results comply with the strictest tolerance ranges. "Of course, we measured all the values on our brake tester benches in Győr beforehand, so we tried to be prepared for all the requirements and performance measurements imposed by the Chinese standard. Consequently, we made complete efficiency maps, speed measurements, tested different functions on the performance brake tester benches, and conducted durability tests to see how resistant the drive was to external environmental influences such as salt road surfaces, immersion in water, dust and heat shock."

"Coordinating the right communication between the Chinese system and our drive was also a very thorough, up-front negotiation task," continues Dávid, whose journey has taken him from internal combustion engines through transformation to PPE drives. He is now working as an engine engineer responsible for engines in the former position of Tamás.

"We used the services of an external company to provide the brake tester bench adaptation of the drives and to help us with the operational management of the logistics process. After all, we had to fly 12 electric drives from Győr to Shanghai and prepare them for a complex test process. The Chinese have also prepared the ground for a fast, smooth on-site implementation of this based on our order and professional coordination."

The three young men also work closely together in their day-to-day routine to improve electric drives, so they have also done a great job 8,000 kilometres away from their home. They were assisted in their travel by the company's Travel Management, where the experiences and information from previous missions are pooled. So even though they were prepared, they were still amazed when they had to scan the QR codes on their phones when it came to paying in shops and restaurants...

"You can only really believe how digitised China is by experiencing it on the spot. We practically never used credit cards or cash during our time there, except when I came across 10 yuans in the street," Laci says with a smile. Even old pensioners use their smartwatches to pay at the market."

"What was also striking in comparison to the last few years," Tamás continues, "is the predominance of local, Chinese cars in traffic. We have seen many Chinese brands on the road, most of them electric or hybrid, previously unfamiliar to us. Thus, even while walking along the dual four-lane road, you could still have a conversation at a normal speaking volume, with only the hum of cicadas providing the background noise. And there was no smog at all. It is striking how extensively Chinese cars are equipped with electronic devices, most of which drivers do not even necessarily make use of. Instead, they actively use the accelerator and the brake."

While our returning colleagues had an extraordinary experience, the PPE electric drives produced in our company can continue to travel the roads of China in our premium Group vehicles with accreditation from the Chinese authorities.