“The transformation process in the automotive industry requires our business model to be adaptable in order to ensure the continued success and future viability of our company in a changed environment. Audi Hungaria has always relied on the high level of expertise of its employees which has been developed not only in the area of manufacturing activities but also other services. In addition to being a key player in the Volkswagen Group’s production network, our company contributes to the successes of the Volkswagen Group as a competence center, building on our broad service portfolio. The high-level and extensive knowledge concentrated in our competence center makes us unique within the Volkswagen Group and, by creating a new business model, will ensure the long-term success of Audi Hungaria. Our goal for the future is unchanged—to achieve and communicate long-term business successes that make a real impact,” said Dr. Patrick Heinecke, Member of the Board of Management of Audi Hungaria responsible for Finance, IT, Procurement and Compliance.

Technical Development

Audi Hungaria’s Technical Development celebrated the 20th anniversary of its operations in 2021. In terms of its size, Powertrain Development and Vehicle Development, employing 550 highly skilled specialists, is AUDI AG’s third largest technical development center and provides development services to almost the entire Volkswagen Group.

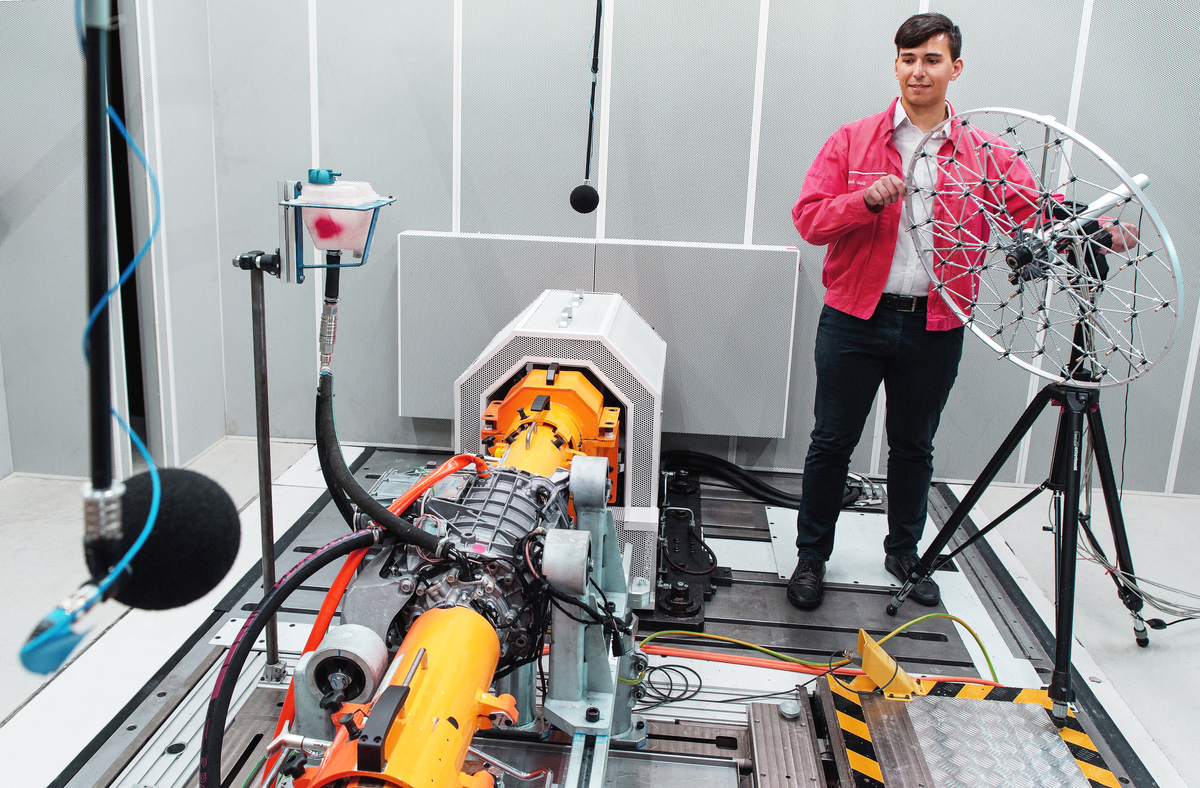

Powertrain Development executes comprehensive development projects for various petrol and diesel engines, as well as electric drives. As part of the development process, Powertrain Development covers the full range of the development spectrum from design, thermodynamic testing and numerical simulation to dynamometer tests. As a result, Technical Development can rely on, among others, 17 combustion engine tests, 3 electric axle drive tests, 2 acoustic tests and 1 climatic dynamometer test. Thanks to its leading role in the development of several powertrain types, the area, which is growing rapidly in terms of both headcount and quality standards, has been managing international drive technology projects as well. The core tasks of Technical Development in Győr also include development support for the series production of various powertrains.

From concept development to the production support phase, Vehicle Development answers questions on heat, energy and water dissipation, ground clearance, strength and acoustics, maintains product data and verifies technical compliance on a project basis. Its main area of expertise is the virtual development of overall vehicle properties using numerical simulation procedures. In addition, Technical Development specializes in testing powertrains and vehicles in the test center and conducting track tests under operational loads of near-road conditions. For these, 1 acoustic test chamber, 1 roller and 2 skid steering dynamometers and various strength measurement stations are all at disposal.

Over the next few years, Technical Development will expand in the spirit of electromobility: in the coming years, Audi Hungaria will invest a double-digit EUR million amount in Technical Development in Győr. This will primarily involve the installation of a new dynamometer for the development of electric axle drives and related transmissions, as well as an upgrade of the existing dynamometer infrastructure.

Financial services

In the area of products and vehicle systems, Controlling assumes full responsibility for making product calculations, setting financial targets and assessing financial impacts with a view to powertrain, body and battery systems. The amount of material costs of Audi managed by controlling specialists in Győr is more than EUR 1 billion every year.

Audi Hungaria’s tax experts are responsible for Hungarian and international tax matters and liabilities. Their main tasks include customs clearance of goods from non-EU countries, optimizing customs costs. They are also responsible for monitoring changes in customs legislation and putting them into practice.

Audi Hungaria’s finance specialists do the processing and accounting of AUDI AG’s incoming invoices. This includes, among others, the checking and validation of incoming vendor invoices and their tax content. The company is currently building up its activities related to the issuance of AUDI AG’s outgoing invoices.

IT

The IT Shared Competence area provides more than twenty different services to more than 200 sites of the Volkswagen Group. Its activities range from the operation and development of SAP applications and SAP license management to the development of IT applications for Shop Floor Management, for all Audi factories. Audi Hungaria’s IT DevOps team works in a state-of-the-art cloud-based environment to continuously improve applications.

In addition to the many IT services provided to Volkswagen Group’s brands and companies, Audi Hungaria’s IT is responsible for a cross-Group working group tasked with developing future Group standards for the SAP technology stack. In this context, Audi Hungaria’s IT team is working closely with experts from other brands in the group.

Procurement

Almost all procurement functions are represented in the service portfolio of Procurement in Győr. In addition to its core tasks such as general, series and project procurement, cost and value analysis and parts purchasing are also included in the competence profile of Procurement. For example, series procurement purchases parts for the Group’s 57 production sites in 13 different countries. The area is responsible for around 33,000 different types of series parts, with a turnover of nearly EUR 2.5 billion in 2021. The parts procured by Audi Hungaria’s Procurement include screws, gearbox modules, plastic and body parts.

Supply Chain

As a key element of Audi Hungaria’s vehicle manufacturing and the Audi Supply Chain matrix organization, Audi Hungaria Supply Chain is providing needs-based supply chain services to production in a complex environment. To this end, the area manages a global network of suppliers and various logistics providers and maintains an in-house material flow to the points of installation of the parts. In addition, Supply Chain delivers Audi models manufactured in Győr to customers in 122 countries around the world. The area is also active in shaping the future of supply chain services by developing innovative logistics processes, focusing on digitalization, automation and sustainability of processes in logistics.